Repair underground water line – Repairing underground water lines is crucial for maintaining water supply and preventing costly damage. This guide explores the entire process, from diagnosis and assessment to repair methods, materials, safety considerations, and even preventative measures. The importance of a proper repair cannot be overstated; a broken water line can lead to significant water loss, property damage, and inconvenience.

We’ll delve into the different types of underground water lines, common causes of breaks, and a comparison of various repair techniques. From trenchless repair to pipe bursting, each method will be analyzed for its strengths, weaknesses, and suitability for different scenarios.

Introduction to Underground Water Line Repair

Underground water lines are crucial for our daily lives, providing a reliable source of water for homes, businesses, and communities. However, these often-hidden pipelines are susceptible to damage, leading to significant disruptions and costly repairs. Leaks, breaks, and complete failures can result in water shortages, property damage, and environmental contamination. Understanding the various types of lines, potential causes of failure, and available repair methods is essential for preventing and mitigating these issues.A proper understanding of underground water lines, their vulnerabilities, and available repair strategies is critical to maintaining a safe and reliable water supply.

This includes recognizing the different types of materials used, the potential for damage from external factors, and the diverse approaches to repair.

Types of Underground Water Lines

Different materials are used for underground water lines, each with unique characteristics and limitations. Common materials include PVC (polyvinyl chloride), copper, and cast iron. Understanding these differences is essential for determining the best repair strategies.

Fixing a leaky underground water line can be a real headache, but sometimes a little DIY know-how can make a big difference. Thinking about tackling a home improvement project? Consider checking out some ideas on do it yourself paint projects for inspiration. Learning how to tackle a fresh coat of paint, or maybe a new backsplash, can help build confidence for your next plumbing project, like that stubborn water line leak.

You’ll be surprised at how much you can do yourself, even when it comes to something as seemingly complicated as an underground water line repair.

- PVC pipes are lightweight, durable, and relatively inexpensive. They are commonly used in residential applications due to their ease of installation and resistance to corrosion. However, they can be susceptible to damage from extreme pressure fluctuations.

- Copper pipes are known for their strength and corrosion resistance. They are frequently used in both residential and commercial applications. Their high cost and susceptibility to punctures from external forces can be a concern.

- Cast iron pipes, while durable and long-lasting, are heavy and prone to deterioration due to rust and corrosion. They are often found in older infrastructure and may require specialized repair techniques.

Common Causes of Water Line Breaks

Several factors can contribute to the breakage of underground water lines. Understanding these causes is essential for preventive measures.

- Tree roots are a significant culprit. As trees grow, their roots can penetrate and exert pressure on the pipes, causing them to crack or break. This is particularly common in areas with dense tree cover.

- Pressure fluctuations, both temporary and sustained, can cause stress and strain on the pipes, leading to leaks or ruptures. Sudden changes in water demand or pressure surges can have a considerable impact.

- Age is a significant factor. Over time, even the most durable pipes can degrade due to corrosion, erosion, and the cumulative effects of pressure and stress. This is especially true for older pipes that may not have been maintained properly.

Repair Methods Comparison

Various methods are available for repairing underground water lines, each with its own advantages and disadvantages. The table below provides a comparative overview.

| Repair Method | Strengths | Weaknesses | Cost |

|---|---|---|---|

| Pipe Bursting | Minimizes disruption, effective for various pipe types, allows for replacement of old pipes. | Can be more complex and expensive for very deep or difficult-to-access locations. | Moderate to high |

| Directional Drilling | Minimizes disruption, avoids excavation in some cases, effective for difficult-to-reach areas. | Can be costly for complex situations and requires specialized equipment. | Moderate to high |

| Excavation and Replacement | Direct access and visibility for repair, suitable for various pipe types and damage scenarios. | Significant disruption, potential for damage to surrounding utilities, can be costly. | Moderate to high |

| Line Relining | Minimizes disruption, less expensive than complete replacement, preserves existing trench. | Limited applicability based on pipe condition, may not be suitable for severely damaged pipes. | Low to moderate |

Diagnosis and Assessment: Repair Underground Water Line

Pinpointing the exact location and extent of a leak in an underground water line is crucial for efficient and cost-effective repairs. A thorough diagnostic process, employing the right tools and techniques, ensures that the repair addresses the problem completely, preventing future issues and minimizing disruption to service. This section details the steps involved in locating leaks, the various tools and techniques used, and the importance of accurate assessments.Accurate assessment of the damage is essential for determining the optimal repair strategy.

A precise diagnosis not only minimizes unnecessary digging but also ensures that the repair is permanent, preventing costly repeat repairs and ensuring the long-term integrity of the water line. The process involves a series of steps, starting with leak detection and progressing to damage evaluation.

Leak Detection Methods

Precise leak detection is paramount for effective underground water line repair. Various methods are employed, each with specific advantages and limitations. The choice of method often depends on the suspected location, soil type, and the complexity of the system.

- Acoustic Listening:

- Dye Tracing:

- Ground Penetrating Radar (GPR):

This method utilizes specialized listening devices to detect the characteristic sounds of water leaking beneath the ground. Trained personnel can pinpoint the leak’s location by listening for subtle sounds like gurgling or hissing. This method is particularly useful for locating leaks near paved surfaces or in areas with limited access. It’s important to note that acoustic listening can be less effective in noisy environments or areas with complex underground structures that may produce similar sounds.

Dye tracing involves injecting a non-toxic dye into the water line. The dye travels with the water flow and leaks will show the dye in the surrounding soil. Specialized equipment is then used to locate the dye, pinpointing the exact location of the leak. This method works well for identifying leaks in accessible areas and is often a cost-effective solution for simple leak detection.

Dye tracing can be less effective in areas with poor soil permeability or in complex systems with multiple water sources.

GPR uses electromagnetic waves to image the underground environment. By analyzing the reflections of these waves, GPR can detect anomalies in the water line, such as cracks or breaks. This technique provides a detailed view of the underground structure, aiding in pinpointing the precise location of the leak. GPR is a powerful tool for detecting leaks in areas with limited access or complex underground structures.

However, its effectiveness can be impacted by soil conditions, like high water content or metallic obstructions.

Assessment of Damage Extent

Once a leak is located, a thorough assessment of the damage extent is necessary. This involves evaluating the size of the break, the surrounding soil conditions, and any potential complications that might affect the repair process.

- Visual Inspection:

- Measuring the Damage:

- Soil Conditions:

After excavation, a visual inspection of the damaged pipe is critical. This allows for an assessment of the extent of the damage, the type of material, and the presence of any debris.

Accurate measurements of the break’s dimensions are critical for determining the size and type of repair needed. This includes assessing the depth, length, and width of the damage.

The surrounding soil conditions can affect the stability of the repair. Analyzing the soil type and moisture content is essential for selecting appropriate repair methods. For example, a sandy soil may require different support measures than a clay soil.

Diagnostic Process Flowchart

The following flowchart illustrates the diagnostic process for underground water line repairs.“`[Insert a flowchart here. The flowchart should visually depict the steps from initial detection to final assessment. It should clearly indicate the methods used at each stage, such as acoustic listening, dye tracing, GPR, visual inspection, and measurement. Each step should be a clear and concise box, and the arrows should indicate the flow of the process.]“`

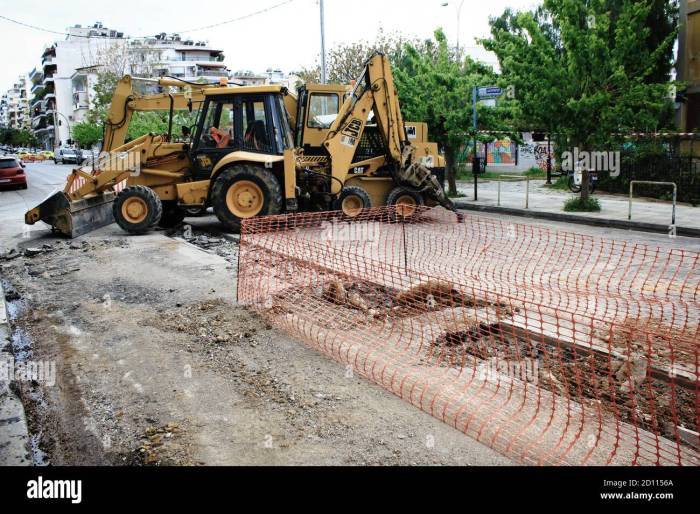

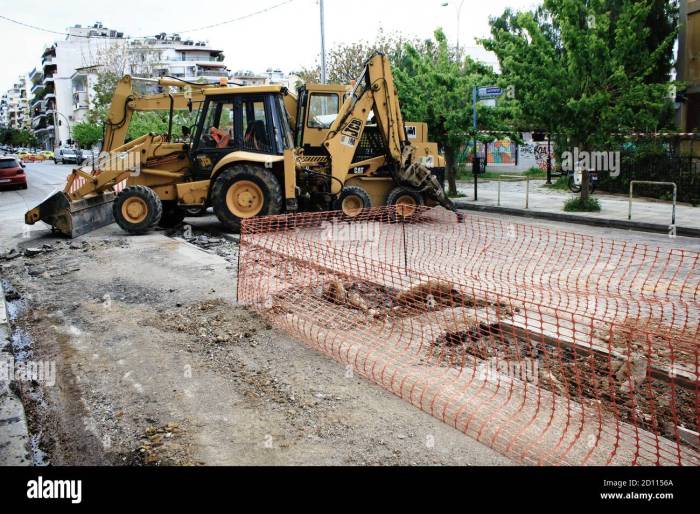

Repair Methods and Techniques

Fixing broken underground water lines requires careful consideration of various factors, including the specific location of the damage, the type of pipe material, and the surrounding environment. Choosing the right repair method is crucial for both efficiency and minimizing disruption to service and the surrounding area. Different techniques offer varying degrees of invasiveness and cost-effectiveness.

Trenchless Repair Methods

Trenchless repair methods offer significant advantages over traditional open-trench excavation, especially in areas with limited access or fragile infrastructure. These methods minimize disruption to the surrounding environment and significantly reduce project timelines and costs. Common trenchless repair techniques include pipe bursting, cured-in-place pipe (CIPP) lining, and directional drilling.

Pipe Bursting

Pipe bursting is a trenchless repair technique that involves pushing a new pipe through the existing damaged one. A specialized tool, called a bursting machine, is used to push a strong, new pipe through the damaged section of the old pipe. This process creates a new pipe in place of the damaged one. Safety precautions are paramount during pipe bursting.

Properly trained personnel must oversee the operation to ensure the integrity of the surrounding soil and structures. Proper bracing and support are essential to prevent ground collapse. Precise planning is vital to avoid disrupting neighboring utilities. Successful pipe bursting repairs have been documented in various scenarios, including situations with tight spaces, complex layouts, and challenging soil conditions.

Cured-in-Place Pipe (CIPP) Lining

CIPP lining involves inserting a resin-impregnated liner into the existing pipe. The liner is then cured in place, strengthening the damaged pipe. This method is particularly effective for repairing corrosion or cracks. The process requires careful preparation and execution. Precise cleaning of the inside of the damaged pipe is necessary to ensure a good bond with the liner.

The cured liner significantly strengthens the pipe’s structural integrity. Examples of successful CIPP repairs include scenarios where corrosion was a major issue, as well as instances where the pipe suffered from significant internal damage.

Epoxy Lining, Repair underground water line

Epoxy lining is another trenchless method that involves applying a thick epoxy resin lining to the interior surface of the pipe. The epoxy hardens, creating a smooth, protective layer that prevents further deterioration. This method is particularly effective for pipes with internal damage. The procedure involves careful preparation of the pipe surface to ensure proper adhesion of the epoxy.

This technique often requires specialized equipment and trained personnel. Successful epoxy lining repairs have been documented in cases where the pipe experienced significant internal damage or corrosion.

Comparison Table

| Repair Method | Pros | Cons | Suitable for… |

|---|---|---|---|

| Pipe Bursting | Minimizes disruption, cost-effective in some cases, relatively fast | Limited pipe sizes, may not be suitable for all pipe materials, potential for soil disturbance | Damaged pipes in tight spaces, complex layouts, and challenging soil conditions |

| CIPP Lining | Restores pipe integrity, suitable for various pipe materials, minimal ground disturbance | Can be more costly than other methods, may require more time for completion, potential for liner issues | Corrosion, cracks, and internal damage in various pipe materials |

| Epoxy Lining | Effective for internal damage, potentially lower cost than other methods | May not be as durable as other methods, limited applications, requires careful preparation | Pipes with internal damage or corrosion |

Materials and Equipment

The success of any underground water line repair hinges on the appropriate selection and use of materials and equipment. Choosing the right components ensures a durable, long-lasting repair that meets the specific needs of the project. Properly equipped crews can efficiently and safely navigate the complexities of underground work, minimizing downtime and potential risks.

Materials for Underground Water Line Repair

The materials used for repairing underground water lines are critical for the longevity and effectiveness of the repair. Common materials include durable PVC pipe, various types of fittings (couplings, elbows, tees), and specialized adhesives designed for watertight connections. The choice of materials is often dictated by the specific type of water line, the soil conditions, and the anticipated pressure levels.

Dealing with a leaky underground water line can be a real headache, but before you start digging, consider prepping your home for spring pests. They’re often drawn to dampness, and fixing a water leak is crucial for preventing unwelcome houseguests. Check out these helpful tips on ways to prepare your home for spring pests to make sure you’re covering all your bases.

Once you’ve addressed potential pest issues, you can then focus on the actual water line repair and get back to enjoying your home.

Essential Equipment for Different Repair Methods

The necessary equipment varies depending on the chosen repair method. A thorough understanding of the equipment required for each method is crucial for a safe and efficient repair process.

| Repair Method | Essential Equipment |

|---|---|

| Open Trench Repair | Excavation equipment (backhoe, trencher), hand tools (shovels, picks, hammers), PVC pipe, fittings, adhesives, protective gear (safety glasses, hard hat), water line pressure testing equipment. |

| Directional Boring | Directional boring machine, specialized drilling tools, survey equipment, pressure testing equipment, protective gear (safety glasses, hard hat), water line inspection tools. |

| Pipe Lining | Specialized lining equipment, pipe inspection tools, pressure testing equipment, protective gear (safety glasses, hard hat). |

Importance of Quality Materials and Equipment

Utilizing high-quality materials and equipment is paramount for a successful repair. Substandard materials can lead to leaks, premature failure, and costly rework. For instance, using inferior PVC pipe might result in a pipe rupture under pressure, requiring a complete replacement. Similarly, faulty equipment can increase repair time, compromise worker safety, and lead to more extensive damage. In contrast, using top-grade materials and well-maintained equipment guarantees a robust and long-lasting repair, reducing the likelihood of future problems.

Specialized Tools for Underground Work

Specialized tools are often essential for effective underground work. These tools are designed to handle the specific challenges of working in confined spaces, navigating complex soil conditions, and ensuring precise measurements. Examples include: pipe cutters, specialized excavation tools for different soil types, and high-pressure water jets for cleaning and inspecting underground pipes. Using the correct tools minimizes the risk of damage to the existing water lines and improves overall efficiency.

Safety Considerations

Safe practices are paramount during any underground water line repair project. Neglecting safety precautions can lead to serious injuries, equipment damage, and environmental contamination. Understanding potential hazards and implementing rigorous safety procedures is crucial for a successful and incident-free repair.Proper safety procedures and the consistent use of personal protective equipment (PPE) are essential for minimizing risks and maximizing the safety of workers involved in underground water line repair.

Failure to adhere to these safety protocols can result in costly delays, severe injuries, and environmental damage. By prioritizing safety, we can ensure the well-being of the workforce and maintain a secure work environment.

Importance of Safety Precautions

Safety precautions are critical for minimizing risks and maximizing the safety of personnel involved in underground water line repair. Failure to follow safety protocols can result in severe injuries, equipment damage, and environmental contamination. The risk of encountering unexpected hazards underground necessitates a robust safety culture and adherence to established protocols.

Potential Hazards and Risks

Underground water line repair presents several hazards. These include the risk of trench collapses, exposure to hazardous materials (like asbestos or lead), and the presence of underground utilities. The confined spaces often involved can exacerbate these risks, requiring specific precautions. Furthermore, working in low-oxygen environments or with heavy machinery adds complexity.

Safety Procedures to Follow

A comprehensive set of safety procedures must be implemented to mitigate potential hazards.

- Thorough site assessment and risk analysis are vital before any excavation work begins. This includes identifying potential utility lines and other underground obstructions.

- Proper trench shoring and sloping are essential to prevent cave-ins. These methods must be tailored to the specific soil conditions and trench dimensions. Failure to implement adequate shoring can lead to serious injuries and fatalities.

- Maintaining clear communication channels between all personnel is critical. A designated communication system should be in place to ensure that instructions are properly conveyed and understood in a timely manner.

- Emergency response plans should be clearly defined and practiced regularly. This includes identifying the location of emergency equipment and establishing procedures for immediate response to incidents.

- Proper respiratory protection must be utilized in case of hazardous gases or fumes. This includes ensuring that respirators are properly fitted and maintained.

Proper Use of Personal Protective Equipment (PPE)

Appropriate personal protective equipment (PPE) must be worn and maintained throughout the entire repair process. This includes:

- Hard hats provide protection from falling debris. They must be worn at all times when working in or around trenches.

- Safety glasses or goggles protect the eyes from flying debris, chemicals, and other hazards. Ensure that the lenses are clear and in good condition.

- High-visibility vests increase visibility and help to prevent accidents. These are crucial for workers who are working in areas with limited visibility.

- Steel-toe boots provide protection for the feet from falling objects or other hazards.

- Gloves provide protection from cuts, abrasions, and chemical exposure. The type of glove should be chosen based on the specific hazards.

- Hearing protection is vital in noisy environments. Earmuffs or earplugs are crucial to prevent hearing damage.

Cost and Timeline

Understanding the financial implications and project duration is crucial for any underground water line repair. This section details the typical costs and timelines associated with various repair methods and project sizes, highlighting factors that influence these estimations. Accurate cost and timeline projections are essential for effective budgeting and project planning.

Typical Costs

Project costs for underground water line repairs vary significantly based on several factors, including the complexity of the damage, the size of the affected area, and the specific repair method employed. Simple repairs, such as replacing a few feet of damaged pipe, can range from a few hundred to a few thousand dollars, while extensive repairs affecting larger areas or involving more complex trenching and pipe replacement can cost tens of thousands of dollars.

Repair Method Costs

- Excavation and Direct Repair: This method involves digging a trench to access the damaged section. The cost largely depends on the length of the trench and the depth of the excavation. Labor costs, equipment rentals (excavators, backhoes), and material costs (pipe, fittings) all contribute to the total. Simple repairs, less than 20 linear feet, may cost between $1,500 and $5,000.

More extensive repairs can easily exceed $10,000.

- Pipe Bursting: This method is often more efficient and less disruptive than traditional excavation. The cost generally includes specialized equipment rental, labor, and material costs. A pipe bursting project for a small diameter pipe (4-6 inches) could cost between $3,000 and $8,000, while larger projects might exceed $15,000.

- CIPP (cured-in-place pipe): This lining method is often less expensive than complete replacement for smaller repairs and is less disruptive than excavation. Costs depend on the pipe’s length and diameter. Typical costs range from $2,000 to $10,000 for a short section, and significantly higher for longer, larger-diameter pipes.

Project Size and Cost Correlation

The size of the project significantly impacts the overall cost. Smaller projects, affecting a limited area, will have lower costs compared to larger projects involving extensive trenching and replacement of significant sections of pipe. Factors like the depth of the water line, the presence of obstacles, and the type of soil encountered also influence the cost.

Project Timelines

| Project Size | Estimated Cost | Timeline (Days) |

|---|---|---|

| Small (under 20 linear feet) | $1,500 – $5,000 | 3-5 |

| Medium (20-50 linear feet) | $5,000 – $10,000 | 5-7 |

| Large (50-100 linear feet) | $10,000 – $20,000 | 7-10 |

| Very Large (over 100 linear feet) | Over $20,000 | 10+ |

This table provides a general guideline. Actual timelines may vary based on factors like the complexity of the repair, access to the site, and local permitting procedures.

Factors Affecting Cost and Timeline

- Complexity of Damage: A simple leak can be fixed quickly and affordably. Complex issues, like multiple breaks or damage to surrounding infrastructure, will increase both cost and timeline.

- Soil Conditions: Difficult or rocky soil can significantly increase excavation time and cost. Soft soil may also pose challenges.

- Location: Access to the site, the presence of utilities near the water line, and local regulations can all affect both cost and timeline.

- Permitting and Approvals: Obtaining necessary permits and approvals can delay the project. Local regulations and procedures can vary greatly.

- Materials: Fluctuations in material costs (such as pipe and fittings) can affect the total cost of the project.

Accurate cost and timeline estimations require careful assessment of these factors to ensure the project is well-planned and executed effectively.

Environmental Impact

Repairing underground water lines, while crucial for maintaining essential services, can have significant environmental implications. Minimizing these impacts requires careful planning, execution, and a commitment to environmentally conscious practices. The surrounding ecosystem, including soil, water quality, and wildlife, needs to be considered throughout the entire repair process.Careful consideration of the potential environmental footprint is vital. This includes evaluating the environmental regulations and guidelines specific to the location of the repair.

Environmental sensitivity varies considerably depending on the geographical area, and adhering to local standards is critical.

Potential Environmental Concerns

Several potential environmental concerns need careful consideration during underground water line repair. These include soil disturbance, water contamination, and disruption to the local ecosystem. Uncontrolled excavation can cause erosion and sedimentation, impacting nearby water bodies and affecting the habitats of aquatic life. Improper disposal of excavated materials or chemicals used during the repair process can contaminate the soil and groundwater.

Mitigation Strategies

Effective mitigation strategies are essential to minimize the environmental impact of underground water line repairs. These strategies include careful site preparation, the use of appropriate excavation techniques, and proper waste management. Minimizing soil disturbance is a key component. Using trenchless repair methods whenever feasible can significantly reduce the need for extensive excavation.

Fixing a leaky underground water line can be a real headache, but sometimes the best solutions involve thinking outside the box. For instance, if you’re looking for creative ways to enhance your kitchen’s aesthetic, exploring vaulted kitchen ceiling ideas can provide inspiration. Vaulted kitchen ceiling ideas offer unique design possibilities, from intricate beams to stylish lighting fixtures, and you might find some unexpected solutions for a well-planned repair.

Ultimately, addressing that water line issue efficiently is key.

Minimizing Disruption to the Surrounding Environment

Minimizing disruption to the surrounding environment is crucial. Precise and controlled excavation techniques can limit the area affected. Using temporary barriers and erosion control measures can prevent soil erosion and sedimentation. Restoring the disturbed area to its original condition is crucial. This involves meticulous backfilling, proper compaction, and revegetation where necessary.

Employing specialized equipment and techniques can also reduce the impact on surrounding vegetation and wildlife. For example, using vibration-dampened equipment can lessen noise and disruption to nearby habitats.

Environmentally Friendly Materials and Practices

Employing environmentally friendly materials and practices is a vital aspect of minimizing the environmental footprint of the repair project. Using recycled or sustainable materials for backfilling and construction minimizes the strain on natural resources. Choosing non-toxic and biodegradable materials for any repair chemicals used is crucial. Implementing water-efficient practices during the repair process conserves water resources. Strict adherence to local regulations concerning waste disposal is also essential.

For instance, hazardous materials should be handled according to established protocols and regulations to prevent soil and water contamination.

Preventative Measures

Proactive measures are crucial for avoiding costly and disruptive underground water line repairs. By understanding the common causes of issues and implementing preventative maintenance, homeowners and municipalities can significantly reduce the risk of future problems. Regular inspections and maintenance can extend the lifespan of the water lines and prevent unexpected emergencies.Implementing preventative measures is not just about avoiding repairs; it’s about ensuring the reliable and consistent function of the water supply system.

This translates to reduced downtime, minimized disruption to daily life, and ultimately, significant cost savings over time.

Common Causes of Water Line Issues

Several factors contribute to the deterioration and eventual failure of underground water lines. These include:

- Soil Movement: Ground shifting due to freeze-thaw cycles, construction activities, or natural settling can cause stress and cracks in the pipes.

- Corrosion: Exposure to water, oxygen, and certain soil minerals can lead to corrosion of the pipe material, weakening it over time.

- Root Intrusion: Tree roots growing into the pipes can exert pressure, causing them to crack or break.

- Age of the System: Older water lines have a higher risk of deterioration and failure due to accumulated stress and wear.

- Improper Installation: Faulty installation practices can lead to weak joints, leaks, and eventual pipe breakage.

Importance of Regular Inspections and Maintenance

Regular inspections and maintenance are vital for early detection of potential problems. Early intervention can prevent small issues from escalating into major repairs. This proactive approach significantly reduces the chance of a complete water line failure.

Steps to Avoid Future Problems

Implementing preventative measures requires a multi-faceted approach.

- Regular Inspections: Scheduling periodic inspections of the water lines by qualified professionals is crucial for identifying signs of damage or deterioration.

- Proper Installation: Ensure proper installation practices are followed during any new water line construction or repair work. Use appropriate materials and techniques for the specific soil and environmental conditions.

- Protecting from Tree Roots: Implementing root barriers or maintaining a buffer zone around the water lines can prevent root intrusion.

- Proper Backfilling: Appropriate backfilling techniques minimize soil movement and stress on the pipes.

- Monitoring for Leaks: Regularly checking for leaks, either by visual inspection or pressure testing, allows for early detection of small issues before they become large problems.

Preventative Maintenance Checklist

This checklist provides a structured approach to preventative maintenance.

| Task | Frequency | Description |

|---|---|---|

| Visual Inspection | Annually | Inspect for cracks, bulges, or signs of leaks. |

| Pressure Testing | Every 2-3 years | Assess the integrity of the water line by applying pressure and checking for leaks. |

| Root Barrier Installation/Maintenance | As Needed/Annually | Install or maintain root barriers to prevent root intrusion. |

| Soil Condition Assessment | Every 5 years | Evaluate soil conditions and identify any signs of potential movement. |

| Corrosion Monitoring | Periodically (depending on material) | Inspect for signs of corrosion, especially for metal pipes. |

Final Thoughts

In conclusion, repairing underground water lines requires careful consideration of various factors, from accurate diagnosis to environmentally responsible practices. This comprehensive guide has provided a roadmap for understanding the entire process, from the initial assessment to preventative measures. By understanding the different repair methods, materials, and safety considerations, you can ensure a successful and effective repair, minimizing disruption and cost.

Remember, a proactive approach, including regular inspections, is key to avoiding costly future repairs.