Wire size underground circuit cable length is crucial for efficient and safe electrical systems. This guide delves into the critical factors influencing wire gauge selection, from current carrying capacity and voltage drop calculations to the impact of ambient temperature and cable types. We’ll explore various underground cable types, their properties, and the role of installation depth. Understanding cable length’s effect on voltage drop and the practical methods for calculation is essential.

Finally, we’ll touch on safety practices, cost considerations, troubleshooting, and regulatory compliance for underground cable installations.

Choosing the right wire size is not just about minimizing costs; it’s about ensuring reliable power delivery and preventing potential hazards. This detailed analysis will walk you through the necessary steps and calculations to make informed decisions about your underground electrical infrastructure.

Wire Size Selection Criteria

Choosing the correct wire size for underground circuits is crucial for ensuring reliable and efficient power delivery. Incorrect sizing can lead to overheating, voltage drop exceeding acceptable limits, and even equipment damage. Proper consideration of various factors, including current requirements, voltage drop, and environmental conditions, is essential for a safe and effective installation.Selecting the appropriate wire gauge for underground circuits involves a multi-faceted approach.

Understanding the interplay between wire size, current carrying capacity, voltage drop, and environmental factors is critical for ensuring the system’s longevity and performance. This process involves balancing the cost of larger, higher-capacity wire with the potential risks of using smaller, less expensive options.

Factors Influencing Wire Gauge Selection

Several key factors influence the choice of wire gauge for underground circuits. These include the expected current load, the length of the circuit, the allowable voltage drop, and the ambient temperature. Careful consideration of each factor ensures a well-designed and efficient system.

- Current Load Requirements: The anticipated current flow through the circuit is the primary driver for wire size selection. Higher anticipated current demands necessitate larger wire gauges to prevent excessive heating and potential damage.

- Circuit Length: The distance over which the electricity travels significantly impacts the voltage drop. Longer circuits require larger wire gauges to minimize voltage drop, which is crucial for maintaining consistent voltage across the entire circuit.

- Allowable Voltage Drop: Voltage drop is the reduction in voltage along the length of the circuit. Standards and equipment specifications dictate acceptable voltage drop levels. A precise voltage drop calculation is essential to ensure that the system functions as expected.

- Ambient Temperature: Underground environments often experience temperature fluctuations. Higher temperatures reduce the current-carrying capacity of the wire. Selecting wire gauges that can handle expected temperature variations is critical to ensure reliable operation.

Relationship Between Wire Size and Current Carrying Capacity

The cross-sectional area of the wire directly correlates with its current-carrying capacity. Larger wire gauges have a greater cross-sectional area, enabling them to carry more current without excessive heating. This relationship is crucial for determining the appropriate wire size for a given current load.

The current-carrying capacity (ampacity) of a wire is directly related to its cross-sectional area.

The relationship is not linear, however. Factors such as the wire material, insulation type, and installation method influence the exact ampacity. Therefore, wire ampacity tables are crucial for accurate selection.

Importance of Voltage Drop Calculations

Voltage drop calculations are essential for ensuring consistent voltage delivery throughout the entire circuit. Excessive voltage drop can cause equipment malfunction and reduced performance. Precise calculations ensure the chosen wire size adequately minimizes voltage drop within acceptable limits.

Voltage drop = (2

- I

- R

- L) / 1000 (Where I is current, R is resistance per 1000 feet, and L is length)

Impact of Ambient Temperature on Wire Ampacity

Temperature significantly impacts the current-carrying capacity (ampacity) of a wire. Higher temperatures reduce the ampacity due to increased resistance. This is a crucial factor to consider when selecting wire sizes for underground circuits, as temperature variations can occur in the environment. It is important to use ampacity tables specific to the expected operating temperature range.

Wire Gauge Comparison Table

The following table provides a comparative overview of different wire gauges and their corresponding current ratings (ampacity) at a standard temperature. This is a simplified example, and specific values depend on various factors like installation method and insulation type.

| Wire Gauge | Area (mm²) | Approximate Ampacity (Amps) |

|---|---|---|

| 10 AWG | 5.26 | 30 |

| 8 AWG | 8.36 | 45 |

| 6 AWG | 13.31 | 65 |

| 4 AWG | 21.16 | 90 |

Underground Circuit Cable Types

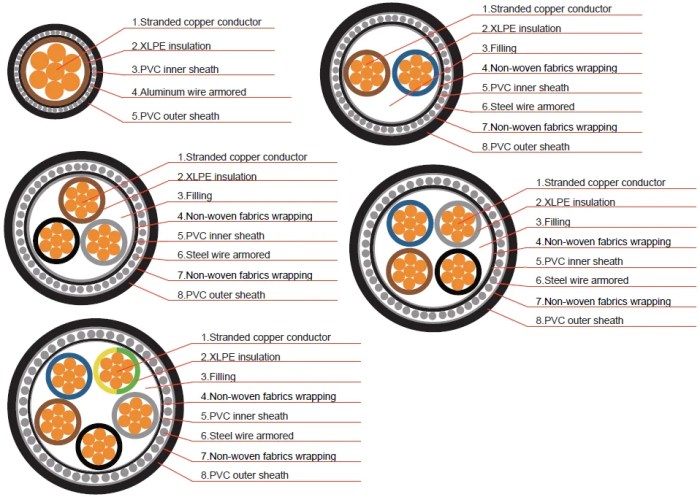

Choosing the right underground cable type is crucial for reliable and efficient electrical distribution. Proper selection depends on factors like the anticipated load, environmental conditions, and installation depth. This section explores the diverse range of underground cables, their characteristics, and suitability for various applications.Different underground cable types are engineered to handle specific demands. This discussion provides a comprehensive overview, covering insulation materials, performance comparisons, and the influence of installation depth on the selection process.

Cable Insulation Materials

Various insulation materials are employed in underground cables, each with unique properties that determine the cable’s performance. These materials must withstand the rigors of the underground environment, including moisture, temperature fluctuations, and potential chemical interactions.

- Cross-linked polyethylene (XLPE): XLPE is a widely used insulation material known for its excellent electrical properties, including high dielectric strength and low loss characteristics. It exhibits excellent resistance to moisture and chemical degradation. This material’s robustness makes it suitable for a variety of applications.

- Polyvinyl chloride (PVC): PVC insulation is a cost-effective option, particularly for less demanding applications. It offers reasonable dielectric strength and resistance to abrasion but may not perform as well in high-temperature or highly corrosive environments as XLPE.

- Thermoplastic: Certain thermoplastic materials provide enhanced flexibility and easier installation, making them suitable for challenging underground environments. Their performance characteristics can vary significantly depending on the specific thermoplastic used.

Cable Performance Characteristics, Wire size underground circuit cable length

The performance of underground cables is evaluated based on various electrical and mechanical properties. These properties dictate the cable’s ability to reliably transmit electrical power and withstand the stresses of the underground environment.

- Dielectric strength: The ability of the insulation to withstand high voltages without breakdown is critical for reliable operation. Higher dielectric strength is preferred for applications involving higher voltage levels.

- Tensile strength: The cable’s ability to withstand pulling and bending forces during installation and throughout its service life is essential for maintaining structural integrity. High tensile strength is crucial for cables in areas with high mechanical stress.

- Temperature rating: The maximum operating temperature the cable can withstand without compromising its performance is a key consideration. Cables operating in warmer environments or with higher current loads require higher temperature ratings.

Impact of Installation Depth

The depth of cable installation plays a significant role in cable selection. Factors like the expected ground temperature, potential for mechanical damage, and the risk of water ingress need to be considered.

Choosing the right wire size for your underground circuit cable length is crucial for electrical safety. Properly sizing the cable ensures enough amperage to power your home appliances without overheating. This, in turn, relates to the design of your living space. For example, when arranging a living room with a fireplace, how to arrange a living room with a fireplace consider the placement of the fireplace and the potential need for extra outlets for lighting and heating.

Ultimately, accurate wire sizing is key to ensuring your underground circuits operate reliably.

- Thermal stability: Installation depth influences the cable’s temperature profile. Greater depths generally lead to more stable temperatures, impacting the cable’s performance and lifespan.

- Mechanical protection: Deeper installations often provide enhanced protection against mechanical damage from external sources, such as excavation or other ground movement.

- Water ingress: Installation depth influences the likelihood of water ingress, which can impact the cable’s insulation and overall performance. Deeper installations generally reduce this risk.

Cable Type Comparison

The following table provides a comparative overview of different cable types, their typical applications, and key specifications.

| Cable Type | Typical Applications | Insulation | Voltage Rating (kV) | Operating Temperature (°C) |

|---|---|---|---|---|

| XLPE | High-voltage power transmission, distribution | Cross-linked polyethylene | 35-110 | 90 |

| PVC | Low-voltage distribution, residential wiring | Polyvinyl chloride | 0.6-1.2 | 70 |

| Armored | Applications requiring enhanced mechanical protection, such as in harsh environments | Various | Up to 110 | 90 |

Cable Length Considerations

Cable length significantly impacts the performance of underground electrical circuits. Longer runs often lead to voltage drops, which can negatively affect the operation of equipment and devices connected to the circuit. Understanding the relationship between cable length and voltage drop is crucial for proper wire sizing and circuit design.

Effect of Cable Length on Voltage Drop

Voltage drop is the reduction in voltage along a conductor as current flows through it. This reduction is directly proportional to the cable’s resistance, the current flowing through it, and the length of the cable. Longer cables offer more resistance, thus leading to greater voltage drops. This effect becomes more pronounced with increasing current demands. Higher currents necessitate larger wire sizes to minimize voltage drops.

Calculation Methods for Voltage Drop in Underground Cables

Several methods exist for calculating voltage drop in underground cables. A common method involves using the formula: Voltage Drop = (2

- I

- L

- R) / 1000, where I is the current in amperes, L is the length of the cable in meters, and R is the resistance of the cable in ohms per 1000 feet. The resistance value is specific to the wire material and size. This calculation, however, is simplified; more complex calculations account for the specific resistance per unit length of the particular cable type, which may vary based on insulation material and other factors.

Online voltage drop calculators can expedite these calculations by incorporating the cable’s specific parameters.

Significance of Cable Length in Selecting Appropriate Wire Size

Cable length directly influences the wire size needed to maintain acceptable voltage drops. For longer runs, larger wire sizes are required to compensate for the increased resistance and resulting voltage drops. This ensures sufficient voltage reaches the load points, preventing operational issues with equipment. A smaller wire size may lead to significant voltage drop, impacting equipment performance, while an oversized wire is a waste of resources and might be unnecessary.

Use of Voltage Drop Calculators for Different Cable Lengths

Voltage drop calculators are valuable tools for determining the appropriate wire size for a given cable length and current load. These tools typically require inputting the cable type, length, current, and desired voltage drop tolerance. They then calculate the necessary wire size to meet the specifications. These calculators are readily available online and can save time and effort in the design process.

They are particularly helpful for various cable lengths, as the appropriate wire size must be adjusted for each length to maintain acceptable voltage drops.

Influence of Cable Length on Voltage Drop at Various Current Levels

The impact of cable length on voltage drop varies significantly with the current level. Longer cables necessitate larger wire sizes to minimize voltage drop at higher current levels. The table below demonstrates the influence of cable length on voltage drop at various current levels. Note that these values are approximate and depend on the specific cable type.

| Cable Length (meters) | Current (Amps) | Voltage Drop (Volts) – 10 AWG | Voltage Drop (Volts) – 12 AWG |

|---|---|---|---|

| 50 | 10 | 0.2 | 0.3 |

| 50 | 20 | 0.4 | 0.6 |

| 50 | 30 | 0.6 | 0.9 |

| 100 | 10 | 0.4 | 0.6 |

| 100 | 20 | 0.8 | 1.2 |

| 100 | 30 | 1.2 | 1.8 |

Installation and Safety Practices: Wire Size Underground Circuit Cable Length

Proper installation of underground electrical cables is paramount for ensuring the safety and longevity of the system. Neglecting safety procedures can lead to costly repairs, potential hazards for workers, and even catastrophic failures in the electrical network. This section delves into the crucial aspects of burying cables safely and effectively, including trenching, backfilling, and environmental protection.

Safe Practices for Underground Cable Installation

Safe practices are fundamental for minimizing risks during installation and maximizing the lifespan of the underground cable system. Adherence to industry standards and established procedures is critical to preventing accidents and ensuring the integrity of the electrical infrastructure. This includes proper personal protective equipment (PPE), rigorous adherence to safety protocols, and regular communication among the installation team.

Choosing the right wire size for an underground circuit cable depends heavily on the length of the run. Just like ensuring your shelves don’t look cluttered, you need to consider the potential voltage drop. Poor shelf styling can make a room look cramped and unorganized, and likewise, improper wire sizing for underground circuits can lead to voltage drops and other problems.

For a deeper dive into the specifics of avoiding common shelf styling mistakes, check out this helpful guide: shelf styling mistakes to avoid. Ultimately, careful consideration of the cable length is key to a safe and efficient underground electrical system.

Procedures for Burying Cables Underground

Careful planning and execution are essential for burying cables underground. The process must follow established safety protocols to mitigate risks. This involves a thorough understanding of the terrain, soil conditions, and the cable’s specifications. The location of utilities and obstacles must also be considered.

Importance of Proper Trenching and Backfilling Techniques

Trenching and backfilling are critical steps in underground cable installation. These techniques directly influence the cable’s long-term performance and safety. Proper trenching ensures the cable is buried at the correct depth, allowing for adequate protection from environmental factors and mechanical stress. Backfilling, in turn, restores the ground’s integrity and prevents damage to the cable.

- Trench Width: The trench width should be sufficient to accommodate the cable, conduit (if used), and necessary space for future maintenance. The exact dimensions depend on the cable type and size.

- Trench Depth: The depth of the trench must be calculated based on the depth of frost penetration in the area and the mechanical strength of the surrounding soil. Consult local codes for specific requirements.

- Backfilling Material: Using the appropriate backfilling material, such as compacted soil, is crucial for preventing settling and damage to the cable. Avoid using debris or unsuitable material.

Importance of Cable Protection from Environmental Factors

Protecting the cable from environmental factors is vital for its longevity. Moisture, temperature fluctuations, and chemical reactions in the soil can degrade the cable insulation and compromise its performance. Adequate burial depth and the use of suitable cable types are key elements in achieving this protection.

- Cable Insulation: The type of insulation used in the cable directly affects its resistance to environmental factors. Different cables are designed for various soil conditions and climates.

- Soil Conditions: Identifying the specific soil conditions in the area is crucial. Aggressive or corrosive soil can degrade the cable’s insulation, necessitating special protection measures.

- Moisture Control: Prevent excessive moisture from accumulating around the cable.

Proper trenching and backfilling techniques are essential for drainage and preventing water accumulation.

Step-by-Step Procedure for Burying Cables (Including Safety Precautions)

A structured procedure is essential for ensuring the safe and efficient burial of underground cables. This includes pre-installation checks, trenching, cable placement, backfilling, and final inspection.

- Site Survey and Planning: Thoroughly survey the installation site to identify potential hazards and obstacles. Mark the cable route clearly and obtain necessary permits. Ensure all relevant underground utilities are identified and marked.

- Trenching: Excavate the trench according to the specified depth and width. Use appropriate excavation tools and machinery.

Properly support the trench walls to prevent collapse.

- Cable Placement: Carefully place the cable in the trench, ensuring it is properly supported and not subject to excessive tension. Follow the cable’s specifications regarding bending radii and handling techniques.

- Backfilling: Carefully backfill the trench, compacting the soil in layers to prevent settling. Use suitable backfilling material, ensuring it is free from debris and harmful substances.

- Cable Protection: Cover the cable with protective material such as conduit or a suitable wrapping, if needed, to shield it from mechanical damage.

- Final Inspection: Conduct a thorough inspection of the completed installation to ensure compliance with standards and the absence of any potential hazards.

Cost Considerations

Choosing the right wire size for an underground circuit involves a delicate balance between performance and cost.

While larger wires offer lower resistance and improved current-carrying capacity, they come with a higher upfront price tag. This section delves into the relationship between wire size and installation costs, exploring various factors influencing cable pricing, and introducing the concept of life-cycle costing.Understanding the interplay between wire size and installation costs is crucial for optimizing project budgets. Different wire gauges and cable types have vastly different price points, directly impacting the overall project cost.

This analysis also considers the long-term cost implications, encompassing the initial investment, ongoing maintenance, and potential replacements over the cable’s lifespan.

Relationship Between Wire Size and Installation Costs

Larger wire sizes generally lead to lower resistive losses and increased capacity, but they also involve higher material costs and more extensive installation efforts. The increased quantity of material needed for larger gauge wires directly translates to higher procurement costs. Furthermore, handling and installing larger cables often requires specialized equipment and labor, thus driving up installation expenses.

Factors Influencing Cable Pricing

Several factors contribute to the price of underground circuit cables. Material costs, particularly for copper or aluminum, are significant drivers. Manufacturing processes, including the extrusion or drawing of the cable, influence the price. The complexity of the cable design, including the number of conductors, insulation materials, and shielding, also impacts the cost. Geographic location and market conditions can also play a role in cable pricing.

Examples of Cost Comparisons

Consider a project requiring 1000 feet of underground cable. A 10 AWG copper cable might cost $2.50 per foot, while a 4 AWG copper cable could cost $5.00 per foot. The installation costs would likely differ even more dramatically, with the larger cable requiring specialized equipment and potentially more labor hours. Similar comparisons can be made between different cable types, such as armored cables versus non-armored cables.

The choice depends on the specific project requirements and the associated risk of damage.

Life-Cycle Costing

Life-cycle costing is a crucial aspect of evaluating the total cost of ownership for an underground cable installation. It considers not only the initial investment but also the long-term operational costs, including maintenance, potential replacements, and the impact on energy efficiency over the cable’s lifespan. A smaller wire size might seem cheaper initially, but higher energy consumption due to higher resistive losses could offset the savings over time.

Cost Estimations for Various Wire Sizes and Cable Types

| Wire Size (AWG) | Cable Type | Material Cost (USD/ft) | Installation Cost (USD/ft) | Total Estimated Cost (USD/ft) |

|---|---|---|---|---|

| 10 | Non-armored | 2.50 | 1.50 | 4.00 |

| 8 | Armored | 3.75 | 2.25 | 6.00 |

| 6 | Shielded | 5.00 | 3.00 | 8.00 |

This table provides illustrative cost estimations. Actual costs may vary based on the specific project requirements, local market conditions, and chosen cable suppliers. The estimations are intended to showcase the potential cost differences among various options.

Voltage Drop Calculations

Understanding voltage drop in underground cable circuits is crucial for ensuring reliable and efficient power delivery. Incorrect sizing can lead to insufficient voltage at the load, impacting equipment performance and potentially causing malfunctions. Accurate calculations are essential for selecting the appropriate cable size to maintain acceptable voltage levels across the entire circuit.Voltage drop, a natural consequence of electrical resistance in conductors, diminishes the voltage available at the load compared to the source.

This decrease in voltage is a critical factor in determining the appropriate cable size for a given application. Factors such as cable length, load current, and cable material characteristics all play a significant role in the magnitude of the voltage drop.

Voltage Drop Calculation Methods

Various methods exist for calculating voltage drop, each with its own level of complexity. For simpler installations, the approximate method can suffice. However, for more precise estimations, especially in complex systems, more sophisticated methods, like the detailed calculation method, are recommended. The choice of method depends on the accuracy requirements and the complexity of the circuit.

Detailed Voltage Drop Calculation Formula

The fundamental formula for calculating voltage drop is based on Ohm’s Law. The formula considers the resistance of the cable, the current flowing through it, and the length of the cable. A more comprehensive formula for calculating voltage drop in a DC circuit is:

Voltage Drop = (2

- I

- R

- L) / 1000

Where:* I = Current in Amperes

- R = Resistance per 1000 feet of cable in Ohms

- L = Length of the cable in feet

This formula is commonly used for single-phase AC circuits. For three-phase systems, the calculations are slightly more involved, needing to account for the specific configuration and phase relationships.

Voltage Drop Calculation Example

Let’s consider a scenario with a 1000-foot underground circuit supplying a load of 50 amps. Using a copper cable with a resistance of 0.1 ohms per 1000 feet:

Voltage Drop = (2

- 50

- 0.1

- 1000) / 1000 = 10 volts

This indicates a voltage drop of 10 volts over the entire length of the circuit.

Table Comparing Voltage Drop for Different Wire Sizes and Cable Lengths

The following table illustrates the impact of wire size and cable length on voltage drop, assuming a constant load current of 50 amps.

| Cable Size (AWG) | Resistance per 1000 ft (Ohms) | 1000 ft Cable Length (Volts) | 2000 ft Cable Length (Volts) |

|---|---|---|---|

| 10 | 0.25 | 5.0 | 10.0 |

| 12 | 0.40 | 8.0 | 16.0 |

| 14 | 0.64 | 12.8 | 25.6 |

This table demonstrates how increasing cable length or reducing wire size directly results in a higher voltage drop. The difference between cable sizes becomes increasingly significant with longer cable runs. These values should be carefully considered during cable selection to ensure adequate voltage reaches the load.

Troubleshooting and Maintenance

Keeping underground electrical circuits in top condition is crucial for reliability and safety. Regular maintenance and swift troubleshooting are essential to prevent costly outages and potential hazards. This section delves into common issues, troubleshooting techniques, and preventative maintenance strategies.Understanding the potential problems and having a proactive approach to maintenance can save significant time and resources in the long run.

This includes identifying potential faults early and implementing corrective actions to avoid escalating issues.

Common Underground Cable Issues

Underground cables, while reliable, are susceptible to various problems. These issues can stem from factors like aging, environmental conditions, or improper installation. Common issues include:

- Insulation damage: Physical damage from excavation or external pressure can compromise the cable’s insulation, leading to short circuits or ground faults.

- Moisture ingress: Water penetration into the cable can cause corrosion of the conductors and insulation degradation, leading to electrical faults.

- Thermal stress: Extreme temperature fluctuations can cause expansion and contraction of the cable, potentially leading to stress cracks and insulation failure.

- Mechanical stress: Repeated stress or movement from surrounding soil can cause damage to the cable’s structure, leading to eventual failure.

- Overloading: Exceeding the cable’s current-carrying capacity can lead to overheating and insulation breakdown.

Voltage Drop Troubleshooting

Voltage drop problems in underground circuits can indicate various issues. These problems can manifest as reduced voltage at the load end of the circuit, impacting equipment performance. Systematic troubleshooting is crucial to pinpoint the root cause.

- Initial Assessment: Carefully measure voltage at different points along the circuit using appropriate instruments. Compare these readings to the expected voltage drop based on the cable’s resistance and current.

- Cable Resistance Measurement: Measure the resistance of the cable section using appropriate test equipment. A higher-than-expected resistance value could indicate damage or aging.

- Load Analysis: Analyze the current demands on the circuit to determine if the load exceeds the cable’s capacity. Overloading can cause significant voltage drop.

- Circuit Configuration Review: Review the circuit’s configuration, including the connection points and the type of cable used. Incorrect connections can contribute to voltage drop problems.

- Corrective Actions: Based on the findings, implement corrective actions such as upgrading the cable size, reducing the load, or reconfiguring the circuit.

Maintenance Schedules

A well-defined maintenance schedule is critical for ensuring the long-term reliability of underground cable systems. This schedule should be tailored to the specific environmental conditions, load demands, and type of cable used.

- Routine Inspections: Regular visual inspections of the cable trench and surrounding areas are crucial for detecting signs of damage, such as trench subsidence or physical damage to the cable.

- Periodic Testing: Periodic voltage drop tests, insulation resistance tests, and ground resistance tests should be conducted to identify any potential faults before they escalate into major issues.

- Environmental Monitoring: Monitor environmental factors such as temperature and soil moisture levels to assess their impact on the cable system and adjust the maintenance schedule accordingly.

Inspection and Testing Techniques

Various techniques are used for inspecting and testing underground cables. These methods are critical for ensuring the integrity of the cable system.

Figuring out the right wire size for an underground circuit cable depends heavily on the length. Longer runs demand thicker wire to handle the potential voltage drop. For example, if you’re tackling a challenging brick fireplace cleaning project, you’ll need the right tools and techniques. Refer to this helpful guide on cleaning brick fireplaces for some inspiration! Ultimately, the right wire size is crucial for a safe and efficient underground electrical system.

- Visual Inspection: Careful visual inspection of the cable trench and surrounding areas is crucial for identifying any signs of damage, such as trench subsidence or physical damage to the cable.

- Non-Destructive Testing (NDT): Techniques like Ground Penetrating Radar (GPR) can detect underground cable damage without disrupting the existing infrastructure. This is a critical tool in identifying potential issues.

- Electrical Testing: Voltage drop measurements, insulation resistance tests, and ground resistance tests are vital to identifying potential faults before they escalate into significant problems.

Common Cable Faults and Causes

A well-structured table outlining common faults and potential causes is provided below. This table is valuable for quickly identifying and addressing cable issues.

| Fault | Potential Causes |

|---|---|

| Insulation Breakdown | Moisture ingress, thermal stress, mechanical stress, aging, overloads |

| Ground Fault | Damaged insulation, faulty connections, corrosion |

| Short Circuit | Damaged insulation, faulty connections, mechanical damage |

| Voltage Drop | Excessive load, long cable runs, inadequate cable size, faulty connections |

Regulatory Compliance

Ensuring your underground cable installations meet all applicable regulations is crucial for safety, legality, and project success. Ignoring these requirements can lead to significant penalties, delays, and even safety hazards. Understanding and adhering to the specific regulations in your jurisdiction is paramount.

Relevant Regulations and Standards

Underground cable installations are governed by a complex web of regulations and standards designed to protect public safety and infrastructure. These regulations address various aspects, including cable types, installation methods, safety procedures, and environmental considerations. Compliance with these standards is critical to avoid costly mistakes and ensure the long-term reliability of the system.

Regulatory Requirements for Different Jurisdictions

Regulations vary considerably between jurisdictions. For instance, in the United States, the National Electrical Code (NEC) provides a comprehensive framework for electrical installations, including underground cables. Local building codes often supplement the NEC, adding specific requirements for the region. In Europe, the IEC (International Electrotechnical Commission) standards are often adopted, with national variations. Canada also has its own set of national and provincial regulations.

Thorough research into the specific regulations applicable to your project location is essential.

Importance of Adhering to Industry Standards

Adherence to industry standards is essential for several reasons. Firstly, it ensures the safety and reliability of the installation. Secondly, it facilitates interoperability between different systems and components. Thirdly, it allows for easier inspection and maintenance. Finally, it reduces the risk of costly rework or repairs due to non-compliance.

Meeting these standards through proper planning and implementation ensures that the project will be in line with best practices.

Obtaining Necessary Permits for Underground Cable Work

Obtaining the necessary permits for underground cable work is a critical step. The process typically involves submitting detailed plans, specifications, and assessments to the relevant authorities. These documents should include information about the cable type, size, length, location, and any potential environmental impacts. Local regulations often specify the required documentation and application procedures. Contacting the local permitting authority well in advance of the project is strongly advised to ensure a smooth permitting process.

Summary Table of Key Regulations and Standards for Underground Cable Installations

| Jurisdiction | Key Regulations/Standards | Key Considerations |

|---|---|---|

| United States | National Electrical Code (NEC), Local Building Codes | NEC provides a general framework, local codes add specific regional requirements. |

| Europe | IEC Standards, National Variations | IEC standards are widely adopted, but national variations must be considered. |

| Canada | National and Provincial Regulations | Specific requirements vary by province or territory. |

| Other Jurisdictions | Country-Specific Regulations | Research the specific regulations and standards in the relevant jurisdiction. |

Final Summary

In conclusion, selecting the appropriate wire size and cable length for underground circuits requires a multifaceted approach. Careful consideration of factors like current carrying capacity, voltage drop, cable type, installation depth, and cost is paramount. This comprehensive guide provides the necessary knowledge to ensure safe, reliable, and cost-effective underground electrical systems. By understanding the intricacies of wire size underground circuit cable length, you can optimize your electrical infrastructure for maximum performance and safety.