Stair handrail and guard code Artikels the crucial safety regulations for building stairways. These codes ensure the safe and functional design of handrails and guardrails, mitigating potential risks and hazards. Understanding the historical context, key components, and applications of these codes is vital for construction professionals and anyone interested in building safety.

This comprehensive guide delves into the specifics of stair handrail and guard codes, covering everything from material requirements to design considerations and enforcement procedures. It examines the evolution of these codes, highlighting their adaptation to changing building practices and safety standards.

Introduction to Stair Handrail and Guard Codes

Stair handrails and guards are essential safety features in building construction. They prevent falls and injuries on staircases, ensuring the well-being of occupants. Proper design and installation, in accordance with building codes, are crucial for safeguarding users. This article delves into the importance of these safety measures, detailing their purpose, types, and the consequences of non-compliance.Building codes are not merely suggestions; they are legally mandated standards designed to protect public safety.

Adhering to these codes, especially concerning stair handrails and guards, is paramount for minimizing risks and liabilities. Ignoring these regulations can lead to serious consequences, from fines to potential legal action and even loss of life.

Definition and Purpose of Stair Handrails and Guards

Stair handrails and guards are protective components designed to prevent falls on stairways. Handrails provide a gripping surface, enabling users to maintain balance and stability, particularly during periods of stress or instability. Guards, on the other hand, act as a barrier to prevent falls from the stairwell, creating a secure and safe passage for individuals.

Importance of Adhering to Building Codes

Adherence to building codes is critical for ensuring public safety. Stair handrails and guards, as critical safety elements, must meet stringent specifications to prevent accidents. Non-compliance can lead to significant repercussions, including substantial financial penalties and potential legal action. Building codes are meticulously developed, incorporating extensive research and analysis of various factors, including accident statistics and material science, to guarantee safety standards.

Potential Consequences of Non-Compliance

Failure to meet building codes regarding stair handrails and guards can result in severe penalties. These may include fines, legal action, and even project delays. Such non-compliance compromises the safety of building occupants and poses a serious risk. In extreme cases, non-compliance could lead to liability issues if an accident occurs. For example, a building owner failing to meet handrail requirements could be held responsible for damages and injuries resulting from a fall.

Types of Stair Handrails and Guards

Stair handrails and guards are categorized based on various factors, including material, design, and intended use. Different types are suitable for different applications.

- Material: Handrails and guards can be constructed from various materials, including wood, metal (such as steel or aluminum), or composites. The choice of material impacts the aesthetic appeal, durability, and cost of the installation.

- Design: Handrails and guards can be designed in different styles, such as straight, curved, or with decorative elements. The design should be functional and aesthetically pleasing while meeting the safety requirements.

- Height and Width: The height and width of handrails and guards are regulated to ensure optimal user safety. Sufficient clearance and grip are critical to prevent falls. Different building codes will specify the exact dimensions depending on the building type and usage.

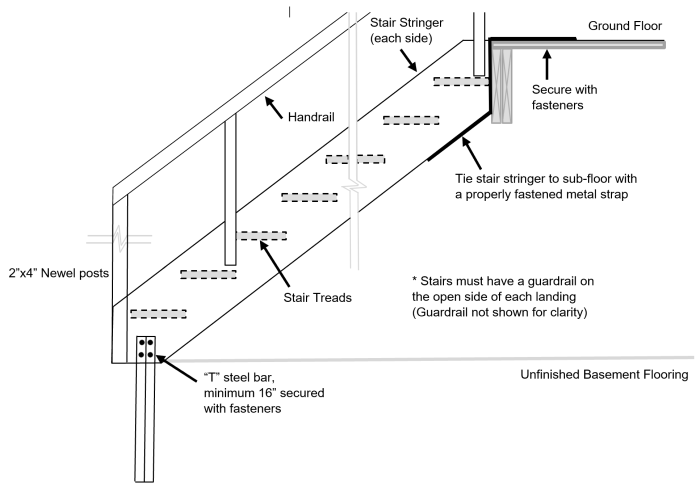

- Installation Method: Handrails and guards must be installed securely to maintain stability and prevent accidents. Specific fastening methods and support structures are mandated by building codes to guarantee safety.

Historical Overview of Stair Handrail and Guard Codes

The evolution of stair handrail and guard codes reflects a continuous effort to improve building safety. Early codes, often lacking standardized requirements, were driven by local incidents and evolving understanding of human factors and engineering principles. Over time, these codes have become more sophisticated and comprehensive, encompassing a broader range of building types and construction methods.These codes are not static; they adapt to new materials, construction techniques, and changing societal expectations.

Understanding the historical context provides valuable insights into the rationale behind current regulations and the challenges in maintaining a balance between safety and practicality in modern building design.

Key Milestones in Stair Handrail and Guard Code Development

Early codes were largely reactive, addressing specific accidents and issues. As understanding of human behavior and structural engineering advanced, codes became more proactive and preventative. Early legislation often focused on minimum requirements, leaving substantial room for local variations.

- The mid-20th century witnessed a surge in building codes, driven by the need to improve safety standards in response to increasing construction activities. This period saw the development of national and international standards, promoting consistency and harmonization across different jurisdictions.

- The incorporation of human factors engineering principles was a significant advancement. Codes began to consider the physical capabilities and limitations of individuals, leading to improvements in design parameters such as handrail heights and guardrail spacing.

- The rise of new building materials and construction techniques prompted revisions to codes. For example, the introduction of prefabricated components required codes to specify appropriate connection methods and safety features for stair components. This demonstrates the adaptability of codes to accommodate technological advancements.

Influential Factors in Code Development

Several factors have shaped the evolution of stair handrail and guard codes. Understanding these influences is crucial for grasping the rationale behind specific regulations.

- Public awareness and advocacy groups played a significant role. Public pressure, often triggered by accidents or near-misses, has driven legislative changes and improvements to safety standards. This demonstrates the importance of community involvement in promoting safer building practices.

- Research on human factors and ergonomics played a key role. Studies on how people interact with stairs and handrails, considering factors like age, disability, and body size, have directly influenced code revisions. For example, modifications to handrail design to accommodate users with reduced mobility have become increasingly common.

- Building practices and construction techniques also influenced code development. As building practices evolved, codes had to adapt to address new construction methods and ensure that safety measures were integrated into the entire process. This highlights the iterative nature of code development.

Motivations Behind Changes in Stair Handrail and Guard Codes

The motivations for code changes have been multifaceted, aiming to enhance safety and address specific concerns.

- A primary motivation was to reduce the incidence of injuries and fatalities associated with stairways. This was evident in the increased emphasis on guardrail strength, handrail gripping surfaces, and compliant connections. This focus underscores the priority of protecting human life in building design.

- Changes were often driven by a desire to adapt to evolving building practices. Codes have accommodated new building materials and construction methods, ensuring safety and consistency across a wider range of structures. This is a continuous process, ensuring that codes remain relevant in a rapidly changing industry.

- Changes were influenced by the need to comply with international standards. Harmonization of regulations between different jurisdictions promotes consistency and interoperability. International collaboration in code development leads to shared best practices.

Comparison of Handrail and Guard Codes Across Jurisdictions

Codes for stair handrails and guards vary across jurisdictions due to local building practices, safety priorities, and historical context.

- Variations can be observed in terms of specific requirements, such as handrail heights, guardrail heights, and materials. These differences reflect the unique needs and circumstances of each jurisdiction.

- There may be differences in how codes address specific construction types, like residential, commercial, or industrial buildings. This is because different building types have different risk profiles.

- International comparisons demonstrate how countries or regions may adopt different standards and priorities. This reveals the impact of diverse cultural values and economic considerations on safety regulations.

Key Components of Stair Handrail and Guard Codes

Stair handrail and guard codes are crucial for ensuring the safety and accessibility of stairways. These codes Artikel the necessary components and specifications to prevent falls and injuries. Understanding these elements is essential for both designers and construction professionals to create safe and compliant stairways.Understanding the key components of handrail and guard codes allows for a comprehensive understanding of safety standards and requirements.

This knowledge is critical in the design and construction of stairways, ensuring that they meet the necessary safety criteria.

Handrail Materials, Dimensions, and Design

Handrails are critical for user support and stability. Their materials, dimensions, and design significantly impact safety. Codes specify appropriate materials, ensuring durability and resistance to wear and tear. Proper handrail dimensions are essential for effective user grip and support. Design specifications address the handrail’s shape and contour, ensuring user comfort and ease of use.

- Materials: Handrails are typically constructed from durable materials such as wood, metal (e.g., stainless steel, aluminum), or composite materials. The choice of material often depends on factors like cost, aesthetic considerations, and the specific environment where the stairway is located. Wood handrails, for example, are common in residential settings, while metal handrails are prevalent in commercial spaces.

The selection must comply with the specific code requirements for the intended use.

- Dimensions: Codes typically dictate minimum handrail heights, widths, and diameters, ensuring a comfortable and secure grip. For example, handrails might need to be 34 inches high to provide adequate support for individuals of various heights. Furthermore, the handrail’s diameter or width should allow for a secure and comfortable grip, and these dimensions are frequently based on anthropometric studies.

These dimensions can vary based on the intended use and specific location of the stairs.

- Design: The design of the handrail must ensure it is continuous and unobstructed for a safe grip. Curved handrails may be used for aesthetic purposes or for specific applications, but the design must maintain continuity and avoid sudden changes in direction or abrupt ends that could pose a hazard.

Guardrail Height, Strength, and Stability

Guardrails are designed to prevent falls from stairways. Specific requirements for height, strength, and stability are essential to ensure safety. The height of the guardrail is crucial for preventing falls, typically specified to prevent individuals from reaching over or falling from the side of the stairway. Adequate strength and stability are critical to withstand anticipated loads and prevent the guardrail from collapsing under pressure.

Understanding stair handrail and guard codes is crucial for safety, but sometimes, a DIY project like building a fire pit can be equally important. For example, a sturdy fire pit, built according to safety guidelines, could offer a lovely gathering space. Knowing how to DIY a fire pit how to diy a fire pit can be a valuable skill, but remember that compliant handrails and guards are non-negotiable when it comes to staircases.

Safety regulations around stair handrail and guard codes are vital to prevent accidents.

- Height: Guardrail height requirements are based on the height of the stairwell and the potential risk of falls. A common requirement is a minimum height of 42 inches from the stair nosing to the top of the guardrail. This ensures that people using the stairs are adequately protected.

- Strength: Guardrails must be constructed from materials and with designs that can withstand anticipated loads. This typically involves calculations based on anticipated use and load capacity. Codes often specify testing procedures to ensure the guardrail meets the necessary strength requirements.

- Stability: The guardrail’s stability is determined by its connection to the structure. The connection must be robust and able to withstand anticipated forces. Factors like the support structure, the type of fastening, and the location of the supports all influence the stability of the guardrail.

Handrail and Guard Connections

Connections between handrails and guardrails, as well as between the components and the stair structure, are critical for ensuring overall stability. Proper connections prevent the system from failing under load or during normal use. Code requirements typically address the strength and durability of these connections.

So, I’ve been diving deep into stair handrail and guard codes lately. It’s fascinating how much detail goes into ensuring safety. Knowing how to properly maintain and install these features is crucial. For example, learning about the proper methods for harvesting sage, which can be found in this helpful guide how to harvest sage , might seem unrelated, but it highlights the importance of precise techniques in achieving a desired outcome.

Ultimately, all these building codes are in place to keep us safe and promote good practices, just like following those guidelines when harvesting sage.

- Attachment: Handrails and guardrails must be securely attached to the stair structure, with specific requirements for the type of fasteners and the spacing of supports. This ensures that the handrails and guardrails remain firmly in place and do not become detached under normal use.

- Spacing: The spacing between supports and connections plays a crucial role in the overall strength and stability of the handrail and guardrail system. Appropriate spacing is essential to distribute the load effectively and prevent any single point from becoming a failure point.

Handrail and Guard Finishes

Appropriate finishes for handrails and guardrails are essential for durability, safety, and aesthetics. Codes specify requirements for finishes to ensure that the materials resist deterioration over time and maintain their integrity under normal use.

- Material Compatibility: The chosen finish should be compatible with the material of the handrail or guardrail to prevent any adverse reactions or degradation. For example, a particular paint type might not be suitable for a metal handrail.

- Durability: The finish should resist abrasion, moisture, and other environmental factors. This ensures the handrail and guardrail maintain their appearance and integrity over time.

- Safety: The finish should not create a slippery surface. Non-slip finishes are often required to prevent accidents.

Application of Stair Handrail and Guard Codes

Stair handrail and guard codes are crucial for ensuring the safety and accessibility of staircases in various building types. Proper application of these codes minimizes the risk of falls and injuries, conforming to established safety standards. These codes are not just theoretical guidelines; they represent a practical approach to preventing accidents and promoting safe building environments.Understanding the diverse applications of these codes across various stair designs and building types is paramount.

This involves appreciating the specific requirements for different configurations and recognizing how those requirements adapt to the particular needs of each structure. A comprehensive knowledge of these applications is vital for architects, engineers, and construction professionals.

Stair Design Variations and Code Applications

Different stair designs require tailored code applications. Straight staircases, for instance, have different specifications compared to curved or winding staircases. The geometry and layout significantly influence the safety requirements. Understanding these differences is crucial for adherence to building codes.

Speaking of safety codes, did you know stair handrail and guard codes are crucial for preventing accidents? They dictate everything from the height of the handrail to the spacing between balusters. Think about how cozy a warm bedroom can be, especially when you’re trying to avoid cranking up the thermostat. There are plenty of ways to warm up your bedroom without running the heat, like using ways to warm up the bedroom without running the heat , and then remember to always check the handrail and guard codes to ensure safety for everyone in your home.

Proper installation and adherence to these codes are essential for peace of mind.

- Straight Staircases: These staircases, with their linear geometry, present straightforward applications of handrail and guard codes. The codes often specify a consistent handrail height and guardrail height along the entire length of the stair. For example, a typical straight stair, common in residential homes, often requires a 34-inch handrail height and a 42-inch guardrail height.

- Curved Staircases: Curved staircases, frequently found in homes and commercial spaces, demand specific considerations. The curvature introduces unique challenges for ensuring adequate handrail and guardrail placement. The curvature itself impacts the required height and width of the guardrail, making curved stair safety different from straight stair safety. For instance, a curved stair might need a 36-inch handrail and a 44-inch guardrail to meet the code requirements.

- Winding Staircases: These complex stair designs, common in some residential and commercial settings, often have multiple turns and changes in direction. Codes must account for the increased risk of falls in these complex configurations. The design of the handrail and guardrail must be carefully planned, taking into account the unique geometry of the stair.

Building Type Considerations

The application of stair handrail and guard codes varies depending on the building type. Residential structures, commercial spaces, and public buildings all have unique safety concerns. The level of risk and potential for exposure to the public dictates the specific code requirements.

- Residential Buildings: Codes for residential buildings often focus on ensuring safety for occupants, considering the typical use and occupancy patterns. These codes emphasize ease of use and accessibility for residents. The requirements may be less stringent compared to commercial spaces, but still crucial for safety.

- Commercial Buildings: Codes for commercial buildings, encompassing offices, stores, and restaurants, often prioritize the safety of a larger number of occupants and the potential for greater exposure to public use. The codes in these situations are often more stringent than in residential buildings.

- Public Buildings: Codes for public buildings, like schools, hospitals, and government facilities, typically have the most stringent requirements due to the large number of occupants, including vulnerable populations. The safety of the public is paramount, demanding meticulous adherence to the codes.

Stair Layout Requirements

Specific stair layouts require specific code applications. The arrangement of the stair, including the number of risers, treads, and landings, directly impacts the design of the handrail and guardrail system. The arrangement of stairs can impact the necessary space and safety measures needed.

- Number of Risers and Treads: The number of risers and treads in a stair significantly affects the handrail and guardrail design. The codes often stipulate the minimum and maximum riser and tread dimensions for safety and accessibility.

- Landings: Landings on staircases require specific guardrail and handrail considerations. The presence of landings often impacts the layout and configuration of the handrails.

- Stair Width: The width of the stair is a key factor in determining the design and installation of handrails and guardrails. Codes often dictate the minimum width needed for safe passage and accessibility.

Summary of Code Requirements

The table below summarizes the code requirements for different stair configurations, highlighting handrail height, guardrail height, and the appropriate material choices.

| Stair Configuration | Handrail Height | Guardrail Height | Material |

|---|---|---|---|

| Straight Stair | 34 inches | 42 inches | Wood |

| Curved Stair | 36 inches | 44 inches | Metal |

Compliance and Enforcement of Stair Handrail and Guard Codes

Ensuring the safety of building occupants is paramount, and adherence to stair handrail and guard codes is crucial. These codes dictate the necessary safety measures to prevent falls and injuries on stairways. Effective compliance and enforcement mechanisms are essential to guarantee that these safety standards are met in all construction projects.The process of ensuring compliance with handrail and guard codes involves a multi-faceted approach, involving various stakeholders.

The successful implementation of these codes hinges on the collaboration and understanding of their roles by inspectors, contractors, and building owners.

Inspector Roles in Compliance

Inspectors play a vital role in verifying compliance with stair handrail and guard codes. Their responsibilities include rigorous site visits to evaluate the design and installation of handrails and guards. They examine whether the components meet the specified dimensions, materials, and structural integrity standards Artikeld in the codes. This inspection process ensures that the stairways meet the necessary safety criteria.

Thorough documentation of findings is also a key component of the process.

Contractor Responsibilities

Contractors are responsible for the accurate implementation of handrail and guard systems. They are expected to adhere to the precise specifications Artikeld in the codes. This includes selecting appropriate materials, ensuring correct installation techniques, and verifying the final product’s compliance with the standards. The contractor’s role is not only to install but also to maintain detailed records and documentation of the entire process.

Building Owner Responsibilities

Building owners have a significant role in ensuring compliance. They are responsible for appointing qualified contractors, ensuring they possess the necessary expertise and licenses. Furthermore, they must ensure that the contractors adhere to the relevant handrail and guard codes. Regular inspections by qualified inspectors are also the responsibility of the building owners. They should also maintain documentation of compliance, including inspection reports, and have a system in place to address any identified violations.

Consequences of Non-Compliance

Non-compliance with stair handrail and guard codes can lead to severe consequences. These may include fines, penalties, and even legal action. The severity of the penalties often correlates with the degree of the violation and the potential risk to public safety. These penalties act as deterrents, emphasizing the importance of adhering to safety regulations. Furthermore, non-compliance can result in delays or project stoppages while corrective actions are implemented.

Enforcement Flowchart

The following flowchart illustrates the steps involved in enforcing stair handrail and guard codes:

[Start]

|

V

Building Permit Application

|

V

Contractor Submits Plans and Specifications

|

V

Inspection by Qualified Inspector

|

V

Compliance Verification

|

V

Compliance Achieved (Pass)

|

V

Project Completion

|

V

[End]

|

V

Non-Compliance (Fail)

|

V

Notification of Violations

|

V

Corrective Action Required

|

V

Re-Inspection

|

V

Compliance Achieved (Pass) or (Fail)

|

V

[End]

This flowchart highlights the sequential steps involved in the enforcement process, from initial application to final compliance.

It demonstrates the importance of proper documentation and re-inspection procedures for non-compliant projects.

Design Considerations for Stair Handrails and Guards

Stair handrails and guards are critical safety features in any building. Proper design ensures user safety and comfort, while also adhering to building codes. This section delves into the key design considerations, emphasizing ergonomic principles, accessibility, innovative approaches, durability, and user-specific design parameters.

Effective stair handrail and guard design prioritizes the safety and well-being of all users, from children to the elderly. The design process must meticulously address the needs of various user groups, ensuring comfort, accessibility, and a long service life.

Ergonomic Design Principles

Understanding user needs is paramount in designing effective handrails and guards. Ergonomic principles focus on creating products that are comfortable and intuitive for users of varying sizes and abilities. This includes factors like handrail height, grip size, and overall shape. Consideration of user reach and posture during use significantly influences the comfort and safety of the design.

Accessibility Design Considerations

Stair handrails and guards must be accessible to all users, regardless of physical limitations. This involves careful planning to ensure compliance with accessibility standards. Factors to consider include handrail height, clearance, and the presence of any necessary ramps or other aids. Handrails should be easily grasped by users with disabilities, providing secure and comfortable support.

Innovative Designs and Enhanced Safety

Innovative designs often incorporate features that enhance safety and usability. These might include adjustable handrails, textured surfaces for better grip, or integrated lighting systems for improved visibility in low-light conditions. A good example would be a handrail that changes its height to accommodate varying user needs.

Durability and Longevity

Ensuring the durability of handrails and guards is essential for long-term safety and cost-effectiveness. Materials selected must withstand the stresses of daily use, including impacts, vibrations, and weathering. Proper installation techniques and regular maintenance are equally crucial to the longevity of these safety features. Using materials resistant to corrosion and degradation, such as stainless steel or high-quality coated metals, extends the service life considerably.

Design Parameters for Different User Groups

A tailored approach to design is necessary to cater to the specific needs of various user groups. This includes children, the elderly, and individuals with disabilities. The following table Artikels some key design parameters for each group:

| User Group | Handrail Height (inches) | Handrail Diameter (inches) | Grip Surface Texture | Additional Considerations |

|---|---|---|---|---|

| Children (ages 3-12) | 28-34 | 1.5-2 | Textured, non-slip | Lower handrails for easier reach, child-friendly design |

| Adults (average height) | 34-38 | 1.5-2.5 | Textured or smooth, depending on material | Standard design parameters, comfortable grip |

| Elderly (65+) | 34-38 | 2-2.5 | Textured, pronounced grip | Wider spacing between handrails, considering reduced grip strength |

| Individuals with Disabilities | Adjustable, 28-40 | 1.5-3 | Textured, tactile feedback | Consider accessibility standards and specific needs (e.g., visual impairment) |

These parameters are general guidelines; specific requirements may vary based on the project and local building codes. Individual needs should always be a primary concern.

Alternative Materials and Technologies

Beyond traditional materials like wood and metal, innovative options are reshaping stair handrail and guard design. These alternatives offer unique advantages in terms of aesthetics, durability, and safety, often influenced by evolving technological advancements. Understanding these choices is crucial for modern stair design, balancing functionality with emerging trends.

Alternative Materials for Stair Handrails and Guards

Material selection significantly impacts the aesthetic appeal, safety, and long-term performance of stair systems. Exploring diverse options allows designers to tailor solutions to specific project needs.

- Glass: Glass handrails and guards offer a contemporary aesthetic, allowing natural light to penetrate through stairwells. Its transparency creates an open, airy feel. However, glass is susceptible to breakage and requires careful design considerations for structural integrity and safety, such as tempered glass and appropriate edge protection.

- Composite Materials: Composite materials, such as fiberglass-reinforced polymers (FRPs), offer a balance of strength, lightweight properties, and corrosion resistance. They are particularly well-suited for high-traffic environments or areas with harsh weather conditions. Composite materials can also be molded into various shapes, providing design flexibility. However, they might not always match the aesthetic of traditional materials.

- Stainless Steel: Stainless steel handrails and guards are known for their durability, resistance to corrosion, and ability to maintain a polished appearance. They are a robust option for high-traffic areas and environments with harsh conditions. The material’s high reflectivity can enhance the perceived space of a stairwell. However, stainless steel can be more expensive than other materials.

- Wood: While traditional, wood offers a warm, natural aesthetic. Different types of wood have varying strength and durability characteristics, affecting their suitability for different applications. Proper finishing and maintenance are crucial to preserve its appearance and longevity. The material’s natural beauty can be a key element in certain design schemes. However, wood can be susceptible to damage from moisture and insects, demanding careful consideration of the local environment.

Impact of New Technologies on Handrail and Guard Design

Advancements in manufacturing techniques and materials science are leading to more innovative and functional stair safety solutions. For example, 3D printing can enable intricate designs and customized solutions.

- 3D Printing: This technology allows for the creation of complex geometries and customized handrail and guard designs, tailoring the solution to specific site requirements. It can also be used to create intricate details that enhance the aesthetic appeal. However, cost-effectiveness and material limitations can be factors to consider.

- Smart Materials: Materials with embedded sensors and actuators can enhance safety by detecting and responding to potential hazards. This includes monitoring handrail load and detecting signs of degradation or structural weakness. These materials hold significant promise for improving proactive safety measures. However, integration with existing infrastructure can be complex.

- Computational Design: Sophisticated computer programs can optimize the design of handrails and guards for strength, safety, and aesthetics. They can simulate various scenarios and identify potential weaknesses before construction begins. This allows for more efficient and effective design, reducing the risk of unforeseen issues during use. The cost of implementing this technology needs to be factored into project budgets.

Emerging Trends in Stair Safety

The field of stair safety is continuously evolving, driven by the need for increased safety, efficiency, and sustainability. Several trends are shaping the future of stair design.

- Sustainability: The use of recycled materials and sustainable manufacturing processes is gaining importance. The environmental impact of materials and construction methods is a key consideration in many new projects. This trend reflects a wider societal focus on ecological consciousness.

- Accessibility: Stair design must increasingly accommodate diverse needs and abilities. Universal design principles are becoming increasingly important in stair safety, ensuring accessibility for all users, regardless of their physical limitations. This is a crucial element of inclusivity in building design.

- Performance-Based Design: Safety standards are evolving to incorporate performance-based criteria rather than relying solely on prescriptive rules. This allows designers to use innovative materials and technologies to achieve desired safety levels. The focus on outcomes over rigid specifications enhances flexibility and creativity in design.

Case Studies and Best Practices

Navigating the complexities of stair handrail and guard codes often requires learning from both successful and unsuccessful implementations. Real-world case studies provide invaluable insights into what works and what doesn’t, helping us refine our approach to prioritizing safety while meeting code requirements. Examining best practices in design, materials, and installation can significantly enhance stair safety and prevent costly and potentially catastrophic incidents.

Understanding the nuances of successful and unsuccessful projects allows us to apply lessons learned to future designs, ensuring that safety is not only a priority but is seamlessly integrated into the design process.

Real-World Examples of Successful Implementations

Successful implementations of handrail and guard codes demonstrate a commitment to safety and adherence to best practices. These projects often result in a well-designed and functional stair system that meets the needs of users and complies with all applicable regulations.

- A public library project implemented handrails with a smooth, non-slip surface, designed to accommodate the diverse needs of patrons, including those with mobility impairments. This proactive design ensured a comfortable and safe experience for all users.

- A school project designed a stair system with substantial guardrails that included a child-resistant design to prevent children from climbing or falling. The system featured rounded edges to avoid potential injury points and utilized materials that were both durable and easy to clean.

Real-World Examples of Unsuccessful Implementations

Analyzing instances of unsuccessful handrail and guard code implementations reveals critical areas for improvement. These examples highlight potential pitfalls in design, materials, or installation, offering valuable lessons for future projects.

- A commercial building project failed to consider the potential impact of wind load on the stair guardrail system. The result was a guardrail that buckled and failed during high winds, posing a significant safety hazard. This case emphasizes the importance of thorough wind load calculations in the design process.

- A residential project employed a handrail material that proved prone to corrosion and degradation over time. This led to the premature failure of the handrail, necessitating costly and disruptive repairs. The example underscores the importance of selecting durable and long-lasting materials appropriate for the environmental conditions.

Lessons Learned from Case Studies

Thorough analysis of both successful and unsuccessful implementations yields valuable lessons that can be applied to improve future projects. These insights focus on factors such as material selection, design specifications, and installation procedures.

- Prioritizing user needs during the design phase, and understanding the anticipated traffic patterns and potential user demographics can contribute to more effective handrail and guardrail systems. A design accommodating diverse user needs, including those with mobility challenges, is paramount.

- Strict adherence to building codes and relevant safety standards, coupled with thorough inspections and quality control measures, minimizes risks associated with inadequate design or installation.

Best Practices for Complying with Codes While Prioritizing Safety, Stair handrail and guard code

Best practices in handrail and guard code compliance go beyond simply meeting minimum requirements. They involve a proactive approach to safety, focusing on the long-term performance and durability of the system.

- Implementing a comprehensive risk assessment during the design phase, considering potential hazards and vulnerabilities, is critical. This assessment should encompass factors such as wind loads, seismic activity, and anticipated traffic patterns.

- Employing durable and corrosion-resistant materials is crucial to ensure the long-term integrity of the handrail and guard system. Selecting appropriate materials for the specific environmental conditions is a significant step towards maintaining safety and preventing premature failures.

Examples of Exceptional Handrail and Guard Design

Exceptional handrail and guard designs prioritize both aesthetic appeal and functional safety. These designs often incorporate innovative solutions that enhance usability and accessibility.

- A museum project utilized a minimalist design for handrails, emphasizing the surrounding architecture while ensuring safety for visitors. This design showcased that effective safety measures can be integrated into a visually appealing structure.

- A residential design incorporated a curved handrail that enhanced the aesthetic appeal of the staircase while providing secure support for users. This example demonstrates how creative solutions can improve both safety and the aesthetic value of the project.

International Standards and Comparisons

Stair handrail and guard codes are not a monolithic entity; they vary across the globe. Understanding these international differences is crucial for ensuring consistent safety standards and facilitating international collaboration in construction and design. Different countries have their own sets of regulations, reflecting their unique socio-economic contexts and priorities. These differences can create challenges for projects with international components.

International standards often aim for a balance between safety and practicality, while national standards may prioritize specific local concerns. The complexities of global harmonization are reflected in the nuanced approaches to handrail and guard design in various regions.

International Standards for Stair Handrails and Guards

Various international organizations develop and publish standards for stair safety. These standards provide guidelines for the design, construction, and installation of stair handrails and guards. Compliance with these standards helps ensure that stair systems meet the safety requirements of different jurisdictions.

Examples of International Standards

- ISO (International Organization for Standardization): ISO develops numerous standards related to building and construction, including standards for stair systems. These often focus on performance-based criteria, which means specifying the desired results instead of prescribing precise methods. These standards are widely recognized and influence national standards around the world.

- CEN (European Committee for Standardization): CEN produces standards for Europe, including detailed specifications for handrail and guard design. These standards tend to be more prescriptive, providing specific requirements for materials, dimensions, and installation methods. They are crucial for ensuring a consistent approach within European member countries.

- ASTM International (American Society for Testing and Materials): ASTM develops standards for the United States and other countries. These standards, like those of the ISO, typically address the performance criteria, but they may have different details concerning materials and testing methods compared to international standards. They serve as a vital resource for North American design professionals.

Comparison of International Standards with US and European Standards

| Feature | US Standards (e.g., ASTM) | European Standards (e.g., CEN) | Key Differences |

|---|---|---|---|

| Handrail Height | Generally specified in terms of minimum height, often referencing the user’s reach. | Often specified with precise dimensions, including minimum and maximum heights. | European standards are more prescriptive, while US standards focus more on performance criteria. |

| Guardrail Design | May include options based on specific application or user groups. | More stringent requirements regarding guardrail design, especially for high-risk areas. | European standards often incorporate a wider range of safety considerations. |

| Testing Methods | Standards often include testing procedures for material strength and durability. | Typically involve comprehensive testing procedures, including load-bearing tests. | Europe may prioritize more rigorous testing protocols to ensure safety standards. |

Differences in Approach to Handrail and Guard Design

The approaches to handrail and guard design vary significantly. European standards often favor a more prescriptive approach, dictating specific dimensions and materials. American standards may focus on performance-based criteria, leaving more design flexibility but requiring careful analysis to ensure compliance. This can influence the cost and complexity of design and construction projects.

Importance of Global Harmonization in Stair Safety Standards

Global harmonization of stair safety standards is crucial for facilitating international trade, collaboration, and the safety of building projects that cross borders. Consistent standards can reduce the risk of accidents and promote a common understanding of safety practices worldwide. Harmonization can also create a unified marketplace, allowing for the efficient exchange of goods and services between countries.

Ending Remarks

In conclusion, stair handrail and guard codes are essential for ensuring building safety. Adhering to these codes ensures the well-being of occupants and the structural integrity of the building. From historical context to modern design considerations, this guide provides a complete overview, emphasizing the importance of compliance and best practices. Understanding these codes is crucial for anyone involved in the construction or design of stairways.